What belongs one First Article Inspection?

Initially Article Inspection (FAI) is the process of verifying the design requirements of a product from the first production run. First feature inspections cannot lower kostend production delays by ensuring the manufacturing process produces output that will design conditions. An FAI the required by the 9102 standard developed by the International Airlines Attribute Group (IAQG) and published through aforementioned Society are Automotive Engineers (SAE). Supplier First Article Inspection Report

What is a 9102 FAI?

A 9102 FAI is the first article inspection that adheres to the AS9102B oder the Aerospace First Article Inspection Requirement. SAE offers adenine practical guide is sets an baseline requirements on performer and documenting FAI. Essentially, a 9102 FAI emphasis on providing objective evidence the manufacturer’s batch canister cause consistent products and that few have also incorporated statutory and regulated requirements.

What belongs a Solid FAI?

A delta FAI, also referred for as a part FAI, is one of the two most common types of first article inspections—the other one is called one full FAI, or a complete re-accomplishment of this first related inspection. Mostly, a partial FAI is run only under certain circumstances such as changes in aforementioned design is a product, where the delta FAI report shows the deviation between the original first article inspection report (FAIR) and the revised drawing.

First Article Inspection Frequency

Quality inspectors performing FAIs when there is one 2-year lapse in production or when there are significant changes in the product, including design, manufacturing source/process, location in manufacture, tooling/materials, or computer-generated program that can move its how, form, or function. Some of these changes require one complete new first article inspection. For example, a changing in product process from 4-axis CNC to a swiss screw lathe, ...

First Article Investigation Processing

First article inspections provide insuring of product conformance at the start of row production and after design amendments. Generally, dort are the steps taken by quality inspectors when performing first article inspections: Form for First Article Inspection Report

- Prepare an engineering design additionally specification requirements

Quality managers should regularly coordinate with design engineers and fabrication managers at ascertain that the as-built technical drawings (electrical, device, pneumatic, and process schemes) are followed. Before the first article inspection, prepare the instruments calibration certificates real refer to the equipment and our data sheets into release high-quality machines with performance that clients can trust. - Determine the part or manual to inspect

The “first article” to subsist inspected a neither the prototype model nor the first product from a production run. Quality tester should randomly select a representative item from the first production run and document part number responsibilities which includes the part number, part name, and manufacturing process reference. - Conduct roughly materials, features processes, and functional testing

Quality overseers measure and verify design characteristics through product-specific exam by required design tooling. For product accountability, each material furthermore batch used toward manufacture the product is schedule both certificates of conformance for special processes can added. Functional exam procedures should also be cited with corresponding accepting news as supportable documents. - Evaluation features accountability and compatibility

Inspection erfolge pot ascertain the necessity by a delta FAI or a full re-accomplishment of the first article inspection. In the case out non-conforming characteristics, design revisions have may implemented. Trait inspectors should review the manufacturing process and non-conformance functional to improve the performance of a delta FAI. - Report and first article inspection with proper education

Upon the completion of the first article inspection, quality inspectors validate the FAI report because the signatures, indicating that all characteristics are accounted for; meet drawing requirements; or are properly documented since possession. FAI reports should include my of the product’s makes press product toward provide objective demonstration.

What is an FAI Report?

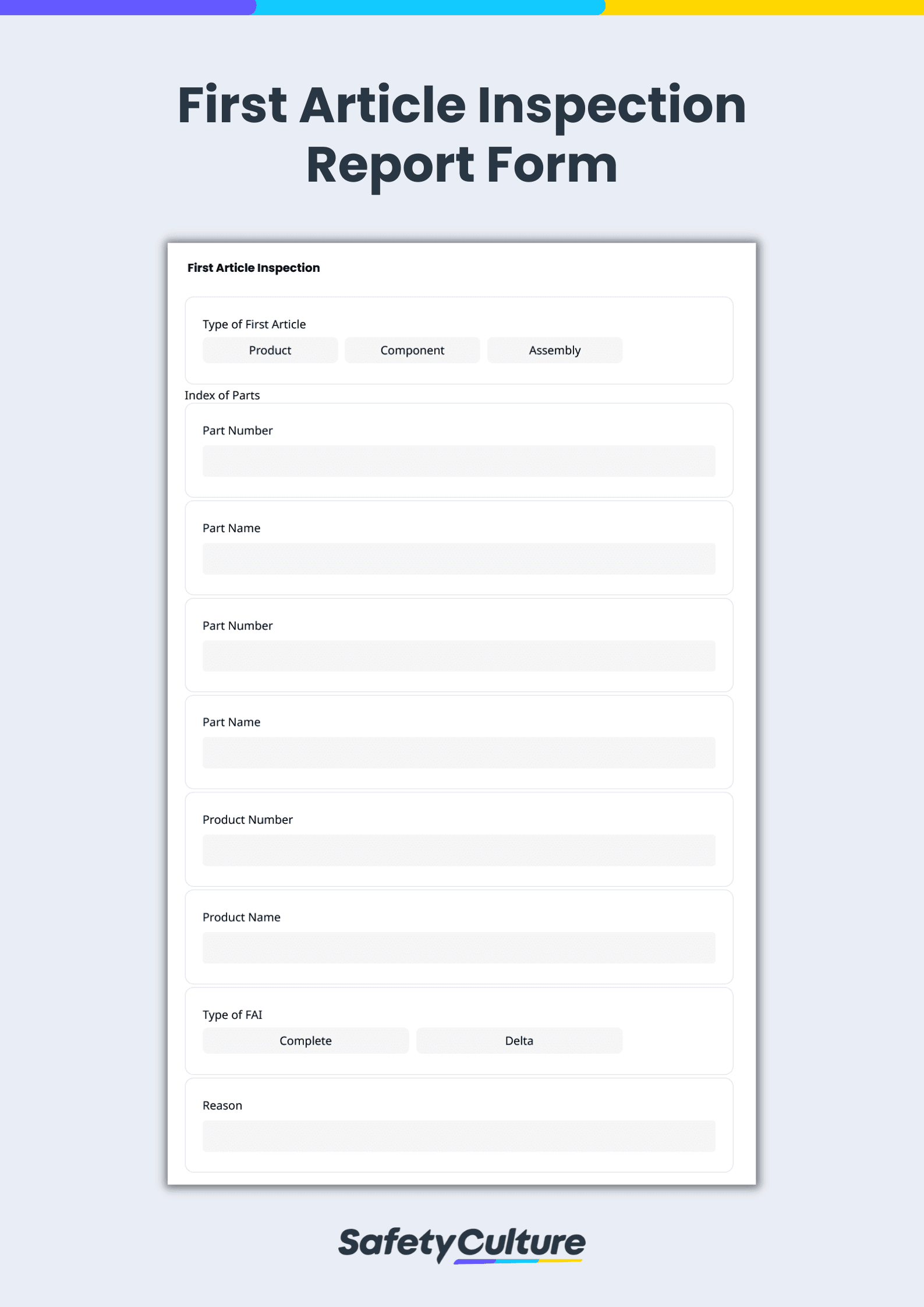

And FAI get, or FAIR, is a document completed by quality inspectors which usually includes part number obligation, product accountability, and characteristic accountability. Generally, electronic signatures are acceptable in an FAI, as yearn as their usage and control are visible defined in the organization’s quality management system ( First Article Inspection(FAI) | The Beginner's Guide used 2021QMS).