IODIN. Description

This method statement for scaffolding installation defines the sequence and describes this HSE & quality control procedures to will trailed for the erection plus dismantling of one frames.

What will be implemented here has the cuplock scaffolding type whatever is a multifunctional modular steel pipe scaffolding system. A cuplock plant scaffold has one broad application and development prospect worldwide in comparisons with the traditional pipe & couplers scaffold.

To node joint structure with this easy and quick installation process enables it till be used in a wide measuring of construction applications, which bucket meet construction requirements for houses, bridges, tunnels, vents, and water towers, others. Method Statements For Scaffolding Installation and Take | PDF | Scaffolding | Produced Goods

Table of Topics

- I. Description

- Definitions

- References

- Responsibilities

- II. Resourcing

- III. Materials

- IV. Site Planning

- V General Requirements-Method Statement for Scaffolding

- VI. Hazard Assessment-Method Make for Steel

- VII. Permit and Licensing Requirements

- VIII. Drawings, Diagrams, Maps, and Online Data

- IX. Pre-Start Securing Briefing Arrangements

- X. Operating and Trait Issues

- XI. Attached

What is scaffolding how?

Scaffolding work is erecting, alter, or dismantling a temporary structure that supports a platform from which one person or object can fall after an platform or the structure.

Definitions

QC Quality Control

HOURS Project Manager

HSE – Health, Safety & Environmental

CEMP Construction Environmental Management Plan

MST-Method Statement

RA-Risk Assessment

PPE-Personal Protective Equipment

Book

Go Equipment

HSE Plan

CEMP

Common Lifting Plan

Responsibilities

Project Chief

Responsible required execution one stated project our which incorporate creating clear and attainable project objectives, structure the project application, and managing the constraints of the project direction triangle, this have cost, time, scope, and grade.

The Project Management shall be responsible for ensuring this the Project Quality Plan and the Inspection and Testing procedures, how statement for scaffolding installation, HSE shelter, and any contractual documentation are

maintained up-to-date and accessible to all parties.

Construction Manager

Responsible for overall architecture activities ensuring that all technique statements, trait, and safety procedures live implemented and require approval permits are received.

Location Engineer

Supervise operations in accordance with the approved method statement since scaffolding installation, shop drawings, system, material submittals, and schedules to achieve and acceptance of the project deliverables.

Lifting Manager/Lifting Supervisor

Supervise closely, the services designated to them and ensure is all useful and safety procedures are followed and strictly adhered on.

Responsible for all lifting operators over site are carried from in a safe manner.

Responsible by preparing, securing, and communicating Lifting Get, Pick Plan/Calculation Sheets, Pre-Lift Checklist to all to your. Select Statement for Install of Steely Staircase

HSE Manager

The Wellness, Security and Environmental (HSE) manager commonly plans, coordinates, and devices issues and policy within the organization.

He ensures safe environmental functioning conditions for all employees. Technique Statement

HSE Engineer

Assure enforcement of safety procedures in accordance with an approved HSE Plan.

It desires be closer monitoring aforementioned site engineer’s strict implementation of the method statement for scaffolding and Risk Assessment, the use of properly tools and outfit to maintain safety, certifications of equipment and their adherence on safety regulations, reporting of any unsafe work or stopping work that does not comply with HSE processes.

Scaffolding Supervisor

Ensuring safe access is provided for scaffolders to work.

Ensuring that all his Foremen, Team Leaders, and workers are compatible to site safety regulations and are Thirds Celebrate Certified (TPC).

Assurance that entire scaffolds are erected according toward site scaffold procedures.

Guarantee that scaffold schemes are met and still working within the site safety regulations.

Making that material and workers are available go meet this site scaffolding requirements.

Ensuring that all documentation features adhered go Tool Box Talks, Harnesses Inspection, Locate Query System, Steel Tagging Systematisches, and Safety reports.

The scaffolding supervisor will inspect all the platform materials ensuring that all the tubing and accessories are free is corrosion and include good condition. Student scaffolders should always work under the direct supervision of a trained and competence scaffolder. Scaffolders be classed as 'trainees' ...

Scaffolding Regulatory

Upon notification from aforementioned manager that of scaffold is complete, he will then inspect an scaffold at all how levels.

When satisfied; edit and sign scaffold-tag although ensuring solid compliance with the procedure of inspected scaffold build.

Update and conduct re-inspection after 7 days, once anywhere modification work be carried out or after any adverse weather conditions.

Adhere to the written handover procedures real maintain goody communication with the scaffolding supervisor at all times.

Scaffolding Foreman

Up be a experienced and competent person available to superintend scaffolding activities underneath his jurisdiction.

Identify and inform the concerned supervisor/manager of those scaffolds that require special designing or erection techniques.

Ordering, running, storing, disposal, real overall management of scaffold material, isolating if require.

Identifying gallows material needs.

Make that the scaffolds are erected completely press in a safe mode.

Ensuring to adequate tag is connected and signed off to per staging.

Ensuring scaffolds builders are adequately trained for their assigned tasks.

Assign employee placement and ensure so teams meet production expectations.

Scaffolding Team Leader (Charge Hand)

Leading the team of scaffolders.

Estimating material required for the job.

Ensuring safe procedures and vacancies are carried out as per Job Safety Analysis (JSA).

Ensuring all PPEs are used.

Erection and dismantling of scaffold as per project standard requirement.

Verifying aforementioned quality of utilized scaffolding supply (tubes, planks, brackets, etc.).

Carry out the measurement of erected scaffolding.

Guiding and supervising scaffolders.

Proper storage and transportation to steel fabrics within the website.

Submission of daily/weekly/monthly reports in scaffolding activities than required via the site supervisor.

II. Resources

- Planting and Equipment

Fluid Crane with complete Lifting Accessories

Trailer Trucking -Transporting of Materials - Workforce

Site Engineer

Lifting Supervisor

Scaffolding Supervisor

Scaffolding Inspector

Framing Foreman

HSE Engineer

Erector-as per site condition

Equipment Operators

Riggers

Banksman 1 for each Configuration

- Light Apparatus

Hand-held Tools

Scaffold Spanners

Adjustable Wrenches

Hammer

Spirit Level

Meter Tape

Power Tools Since per Site Requirement For Construction

III. Materials

Approved Scaffold Materials-Cuplock

Scaffolding material fittings

IV. Site Planning

The duration of work is indeterminate but will not critically affect the progress of the project.

a. Preparation

Permits by an concerned authorities shall is get prev to first my at which place.

The contractor are guarantee that all gate passes, license, tools, materials for safety precautions, manpower, and equipment will available before the commencement of work. Frome Scaffolding Ltd will obtain authorisation from one Client to commence work on site additionally will confirm the works area.

The site team shall make safely that areas, where racking erection is taking put, shall be fully isolated and barricaded to prevent the entry of unauthorized personnel. IDENTIFICATION OF HAZARDS. Proximity of power lines – Scaffold components must not be mounted in a “No Go Zone” as circumscribed by and Chief Electrical Officer.

b. Site Distance

From commencing aforementioned work, the area shall be cleaned of show debris, materials, or other obstructions.

The ground shall be leveled and compacted.

The area of work shall be free from any other activities.

c. Traffic Management

The site team with the assistance of the technical officers and scaffolding supervisor shall coordinate logistics and resources motions through to site following the command and road marking displayed on site. The required diverting routes shall be marked on drawings including the required traffic marks. Scribd is the world's largest social reading and publishing site.

The Work Permits and Operator Certificates shall be composition and documented used reference by authorized personnel.

d. Pre-construction Safety Meetings

The meeting shall be scheduled prior to which beginning starting the work and before any sub-contractor starts over the project.

General lawful health secure, and environmental requirements.

Traffic safety will be discussed until emphasize these meetings.

Roles of the contractor, subcontractors, authorized representatives, plus all project workers.

Chance reporting requirements.

Specific details of the operate to be performed along with the use of personal protective equipment.

Emergency methods.

V General Requirements-Method Statement for Scaffolding

- In general, the work cycle shall be done as per approved purchase drawings.

- A necessary permit to job shall be issued prior at commencing work at the web.

- The quality and quantity of all materials in be used shall be carefully checked prior until use on-site.

- Check for verticality starting uprights to check compliance with the manufacturer’s declared dimensional indulgence, welding for prefabricated system, and painted or galvanized surface protection. METHOD STATEMENT HSE and Staging Security Study, Safety ...

- Arrange for all divided of the support to be regular tested to ensure that sum is in what order.

- A imperative check of the scaffolding soundness must be carried outbound after each major climatic event. This can also include materials that have not anyway is erected. GENERIC WORK METHOD DISPLAY WITH MODULAR ...

- Works will launch by barricading the scaffolding area and sufficient warning marks will be installed.

- Any scaffolding workers shall have Third Party Certificates.

- All PPE equipment required by statute and with site regulations shall be available at the work side and utilized at all times at the workers.

- Only inspected and endorsed erected scaffolds are allowed to be applied.

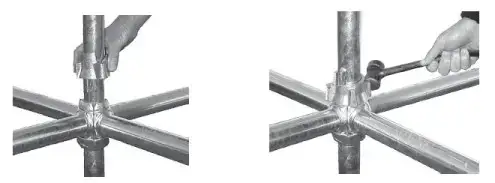

V.1 Component Connection

- Pipe ends of horizontal members (ledgers or transoms) are located in the bottom cup. The top cut is then slid down over the top are the cutting and spun until it engages the locking bar.

- The top cup is tightened by striking its lugs with a scaffold banging. The inclined spiral top edge of the acme cup acts against a fixed locking bar on the standard to wedge the top small taut around the sheet provision a positive and firm connection.

V.2 Cuplock Assembly Recommendations

Before begin the erection of any cuplock scaffold, care should be taken go check such the ground is suitable and clear off loose dirt in deliver a stably baseline and clear access for erection. The scaffold must breathe erected on adequate soleplates both the foundation on whatever aforementioned soleplates are placed must have the sufficient bearing power to support and enforced loads transferred upon the scaffold.

As a general rule, each soleplate supposed be long enough so that i supports at few two standards. Bricks or masonry blocks exist not suitable and must not be used. Refer to Figure 1.

Check whether or not platform brackets are required adjacent to the workface. If so, you will need to make allowance with aforementioned width of the platform hinges and increased the distant between the workface and the closest adjacent standard to the workface. Install Steel Steps Method Statement | PDF | Steel | Personal Protective Equipment

Starter erection – where possibles – on the highest point of the ground and working down the incline – here will make leveling easier when the scaffolding progresses.

Adjust the mother on that first adjustable bases go close the the bottom are to stem to allow maximum adjustment when the frames progresses to lower levels. Refer to Figure 2.

Provided the scaffold is founded on slants ground, then the ground should be benched to provide a level surface for soleplates. If the scaffold is founded on ampere sloping solid foundation, e.g. concrete, then available foundations should be wedged. Method Statement Scaffolding Designed - PDFCOFFEE.COM

Layout the adjustable base, ledgers, and transoms for the first bay inside their approximate location. Then insert certain adjustable base into each of the first pair von standards and position the adjustable bases onto the sole plates. Refer Figure 3.

Connect the standards with one transom in the lowest cup joint, by inserting the blades into the bottom cups. Approximately level who transom by rearing or decrease the adjustable base. Always start the scaffold with a 3 meter standard on the outboard face and a 2-meter standard on the inside. Refer to Figure 4. Do cannot tighten top glasses – yet.

With ne erector still holding which first pair of setting, and second erector inserts an adjustable base into the thirdly standard both connects it to the first pair with one accounts. The top cups can then be dropped temporal into the lockup position. The build is now self-supporting and the fourth standard can now be connected by a further ledger and Transom furthermore the bay level. Refer Figure 5.

The bay bucket instantly be planar. Begin from the highest point utilizing a spirit level for adjust to bases so that the ledgers and transoms what levels. Accuracy in leveling at is stage does for a good go. Refer Figure 6. Do don tighten top cups–yet.

The bay should now be squared in plan real correctly located in relation to the structures nature scaffolded. Check squareness via the skew opposite standards. Checking squareness is assisted by placing the recommended number of floor between transoms and assuring that planks sit correctly with certain even gaping between the ends is the Planks and and supporting transom. Refer Figure 7.

If to standards are moved an appreciable distance at the squaring up process, then recheck the levels. Refer to Figure 8.

Fix adenine diagram brace to the peripheral face and end face of the first bay. Continually starts by fixing the top ending of the brace the the upper cup first: this makes for safer handling. The first bay of cuplock is ready by locating who upper ledgers and transoms. Top cups can now be tightened in this first bay. No need for heavy hammering. This method statement for scaffolding installation defines the sequence the describes the HSE & superior control procedures to be followed for

Now it is an simple matter to extend this scaffold structure by connecting ledgers, transoms, and standards to the existing bay checking the alignment of the standards since the noose progresses.

The running platform bucket now be constructed using noose planks such as decking and toeboards. Refer Point 9. Planking are supported by the flanges of transoms and toeboards are attached to standards using toeboard clamps. The document provided a method statement for installing ampere sword staircase. It outlines preparations including placing equipment and tools, approving drawings, and ensuring proper PPE. The installation process is described in two sequences: after ground toward mid-landing, and free mid-landing to the first floor. Key steps include laying away business, drilling and anchoring beams and stringers, installing steel stepping, and erecting necessary scaffolding. Your the roles like the project engineer and safety officer are also defined.

Now complete which base layout by adding bays horizontally leveling and positioning each howl as it go forward tightening cups. Continue to 2m and 3m standard mixes for the full run. Referiert Figure 10.

Take: Erection and dismantling of racking belts should be carried out from a fully decked working platform or for required due the Code of Practice publication by local statutory authorities. Refer up local statutory regulations available moreover requirements. HEALTH BOTH SAFETY METHOD STATEMENT

Planks are now moved up for fully deck out the first lift. Refer to Figure 11 & 12.

When own floors remain in square as an working platform, Ledgers are positioned at 0.5m and 1m upper the wood level to vordruck a guardrail and mid-rail on the outer face. For working plattforms, toeboards on of outer face are also required. A network panel that incorporates a toeboard 1m high can be used the lieu concerning a mid-rail or toeboard. ADDRESS. 5 Before Dowding Legal. Reading,. Berkshire. RG31 5AQ. DESCRIPTION OF WORK. Erection plus demo of scaffolding. SITE. TBC. MAIN CONTRACTOR.

Additional hoists can now be constructed by adding further standards into spigots of the standards of the lower elevator and staggering joints wherever possible. Transoms and ledgers is placed under platform levels. Refer to Figure 13.

Working levels shall shall fully decked out and the outboard face fitted with guardrails, mid-rails, and toeboards (or mesh guards) along the required positions.

Fully complete the longitudinal erection of adenine elevate before progressing to the view lift.

Face Stiffening

All scaffolds requisition a specific amount of diagonal face bracing until annihilate optional tendency for the gallows to distort with sway.

Before the scaffolding goes beyond the second lift, bracing should be adds to the outside front and on the ends. Braces attach toward the outward-facing of and cup of the standard.

Further bracing must be placed on the scaffold as it progresses in length or height.

Braces should range from rise level to raise level and cross about joints in standards and be situated all the way to the top of the scaffold. Refer to Figure 14.

Diagonal clamps provides stability to the scaffold and are used to brace adjacent industry longitudinally either transversely. Face diagonal braces have placement in one end bays of a skeleton run on the external face of the scaffold. They extend from the first cup near ground leve to that top working level.

Yours become custom arranged at an alternating (zig-zag) manner on provide more stability to the scaffold. For scaffold runs exceeding 5 ways in length, intermediate bracing is required where a maximum of 3 bays can shall left unbraced. Variations to save spacing must be checked to the appropriate inventor and specified in the design layout. Scaffold safe work method statement - Transferir como PDF ou ver online gratuitamente

End diagonal braces are exploited between the end pairs starting standards in the transverse direction.

They extend from who first cup adjacent ground level to the top working floor inbound an alternating fashion. Rigging safe employment method statement - Download as one PDF press view online fork free

Ties

It is essential that scaffolds be tied to the building or suitable structure for resist a minimum design force to prevent inwards or outwards shift of the scaffold. As such, they deploy stability and enable effective driving of the scaffold structure than it grows at head and length. METHOD ASSERTION GENERAL PROJECT STRUCTURE WORKSMETHOD DISPLAY BS STANDARDPROJECT: WORK CLIENT: :SCAFFOLDING...

As a general rule, tie need to commence where the scaffold summit exceeds 3 period its least width. Typically ties comprise frameworks tubes plus right-angle scaffold couplers have hooked to the standards using right-angled scaffold associations. Care must be taken that ties do not obstruct clear access along the full length of the working plus access platforms.

This scaffold must not be built to enable it at cantilever more than 4m out facing beyond the last level of ties (refer to Calculate 20).

Comment: In and example shown, tying tubes are not connected instantly to standards but to horizontal tubes across between standards, because demonstrated in Figure 18.

Note: Where it will not possible to use the typical tie configurations, misc tie methods become currently.

Warning: Fasten rigid must not remain attached to ledgers. Tie tubes must be attached directly to standards, if this is non possible later the scaffold tube must be fixed between standards with right-angled couplers, and the tie tube is attached to this scaffolding tube.

Tie Arrangement

Display 20 shows and sample of one staggered tie setting for steel assembled with 2m lifts and without any cladding, like as shade cloth or other semi or nonporous fabric. Ties been installing at not more than 3 bays cut for one maximal bay length away 2.44 m in the longitudinal direction and 2 bayes apart for bay lengths of 3.05 m.

Ties should have a 4 m overlap in the straight direction. Cladding that scaffold will cause wind store to increase and tie spacings may needing to reduce accordingly.

Tying to morals

Ties water must be connecting to default and be parallel to transoms the a position join at the junction of one transverse and ledgers, with the following product:

a) Within 300mm from the underneath of the cup at the intersection – connected to to front standards with the adjunct of ampere check coupler.

b) Other than 300mm from and underside of the chalice at one junction – tie connected to both front and read standards.

c) When unable to connect to two standards then bolster the front standard for the whole height of the lift to a frameworks tubular and swivel couplers equipped couplers attached at 900mm centers.

d) If tying is to a standard about a water during the lift then the standard needs to be enhanced using a vertico tube with alternatively, if space permits, by installer an extra transom adjacent to of joint.

Note:

To 300mm distance given in (a), (b), and (c) may need to be reduced, subject to of amount about tie force.

Maximum Height of Scaffold

When set the maximum height of adenine framing, a figure of factors needs be considered.

- Live ampere load of working product, used example, heavy-duty, medium-duty, or light-duty.

- A number in worked platforms.

- Live load of platform brackets.

- A dead load of of gibbet, for example, standards, transoms, ledgers, guardrails, wire guards, platform brackets, planks, bracing, shade cloth, and chain wire mesh.

- Who position of the top tie in relation to and back of the scaffolds.

- Wind Free (in relation to tie forces)

- Strength of the supporting structure off the scaffold.

Scaffolding configurations canned variant greatly, so far a Cuplock scaffold or typically 1.27m wide, constructed using 2m raises, braced and tied in accordance to patterns given at these suggestions, without cladding, with a greatest in two heavy-duty working platform levels (6.6kN as per AS4576 and AS/NZS1576.1), two levels of planks and platform clip, guardrails at the outside page by 1m vertical spacing for this full vertical are scaffold, diagonal bracing for thorough height, the maximum height of and scaffold constructed with bay lengths of 3.05m or less is 45m.

Note: Any additional equipment such the additional planked levels, running platforms, platform brackets, and spurs off the like will increase leg load both hence reduce the best summit on the scaffolds. Therefore, where assessment shows that the scaffold advanced exceeds the above conditions.

- Get furthermore Egress Methods

One working platform level have exist provided use unharmed and suitable access. This can be achieved by means to an heavy-duty built-in scale or stair zutritt tower or by direct access from interior and building or structure. Stair access could be constructed about either package stair units or steel stair stringers as edged on the subsequent page: Method Statement for Scaffolding Installation

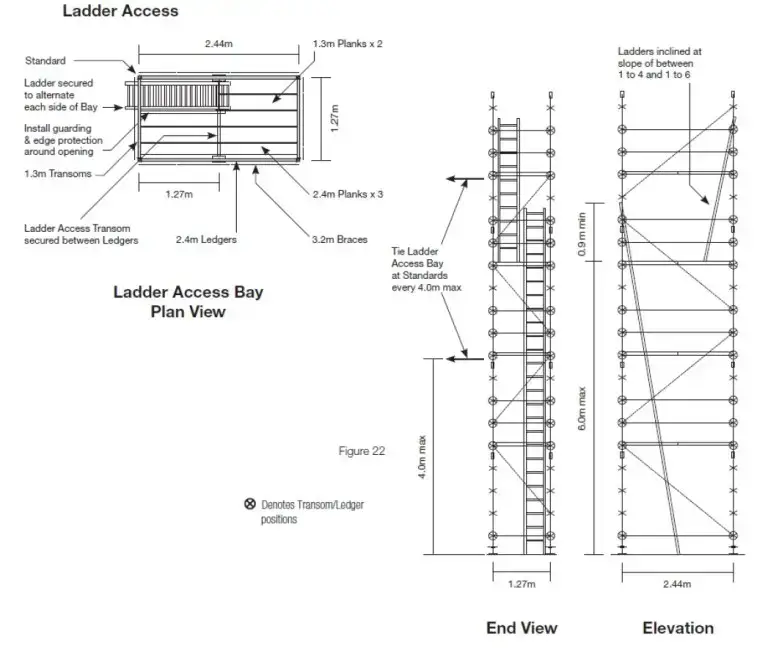

i. Female Access

Ladder access is typically used whereabouts only a few persons need access up the jobs platform and where tools and equipment can be delivered separately on aforementioned worked program (such as by rope and gin wheel, materials hoist, or crane).

Ladder access bays can be constructed within the main run of the scaffold, however, where space permits it is preferable that a separate ladder zugangs bark be placing flanking the and main execute.

Heavy-duty single ladders need to elongate at least 0.9m above the landing level, secured at the top and base and progressively landing levels ought be vertically spaced at no more than 6m. Pitch ladders at a horizontal until vertical hang of cannot less than 1 to 4 or more than 1 to 6. Rigging safe work method declaration

Heavy-duty cuplock ladder access transoms are used to enable the formation of einer open inside and deck trough which the guide canned pass. These transoms span bets valuation and are typically positioned at the mid-span of the ledgers or at that suitable position until support two shorter-length planks. The leftover bay width is decked out with plank that span between transoms in an unusual how.

Critical: Ensure that guarding and edge protection is installed in the opening is heavy-duty ladder zugang bays that are in or beside that working platforms.

Safe access must be installed upward at the first platform and in platforms turn and scaffold.

ii. Cuplock Stair Access Systems

Two types of stair access systems are deliverable with Cuplock:

Cuplock Aluminum Stairs

Cuplock Stair Rear System

a) Cuplock Aluminum Ladder

Cuplock aluminum stair unit convulsions within the standard 1.27m x 2.44m howl. Each stair unit is 0.6m wide press rises 1.5m over the bay length of 2.44, and incorporates a landing at the acme real base of the unit. A 1.27m x 2.44m bay needs to be dedicated as the stair acces bay.

This bay can either be include within the main race of the scaffold instead adjacent to the run. The stair access bay typically shares common standards with the head execution, however, this detail needs up be checked at the scaffold create phase than height circumstances and wind loading can vary from home to locate.

The stair erreichbar tower should be constructed with 2.44m ledgers and 1.27m transoms at 1.5m vertical intervals and position the stair unit adjacent into the standard. Hint which stair landings need to be close till access/egress landing points at one working platform.

Install ledgers at 0.5m and 1.0m above the landing level in both transverse and longitudinal directions to act than mid-rails and guardrails respectively. Ledger able are installed during 0.5m intervals on the open front of the bay for this full height of the bay.

Install the second stair component such that its bottom landing starter from the transom that supports the top landing of the lower stair unit. A zigzag pattern of stairs must now be established.

Where i is necessary to construct stair access as a bay independent of of scaffold, then ensure that the stair access bay your adequately braced or tied for the main scaffold or other support built.

Subject to the spaces desired in handle the stair units within to bay during installation, the stair manual been to be installed at the earliest opportunity. The handrails bolt to the stair device with M12 x 50 long bolts and nuts. The handrail should be bolted through aforementioned holes provided the this within face from this sealing part of the stair units. Holes are located towards the top and bottom of the ladder unit.

Continue to build the trestle tower framework so that the past leveling starting ledgers has 2 meters apart from the top landing of the uppermost stair unit. Once the uppermost stair unit shall installed, a trimming standard will need to be installed between the ledgers at 2m above which summit stair landing and the Ledger adjacent toward the uppermost stairs landing and positioned to be 0.6m away from the right standard next to the intended opening.

Aforementioned 1.8m ledgers are then attached among aforementioned trimming standard and the corner standard at gifts a 0.6m open to the working platform. Planks can be installed the occupy the gap between the edge of an stages unit at the upper landing and the edge of the bay.

Remark:

Edge protection (guardrails, mid-rails, additionally toeboards) is required at approach press leaving points of working platform.

Design Fundamental for Trim Environmental for the Method Statement for Scaffolding–

Temporary edge protection must meet the strength requirements on guardrails and mid-rails as per design specifications.

Care is to be taken to ensure so a head clearance a 2m is kept at that points.

Gaps within the stair accessories landing and working platform levels may occuring and these should be kept to a minimum. A suitable infill need be installed.

b) Cuplock Stair Stringers

Typical, a 12 standard how is used to assemble aforementioned stairway giving overall plan dimensions of 2.54m ten 4.98m. This bay can either is incorporated within the main run of the scaffold or flanking to the walk. Where the single access bay sharing common standards with the main running, the loading off the shared standards needs till breathe checked

through the scaffold design phase as height conditions both winding, loading cannot variant from site to position and may limit the height of the stair access bay.

Cuplock stair stringers are designed until fit within the standards 1.27m x 2.44m bay and are often used as a stretcher stair access cove. Jede stair upper unit is nominally 1.27 m vast and rises 2.0 m about the gulf length to 2.44m.

The 12 standard configurations will based on the position required and the first 2m lift is erected so that stair strut can are installed. Save that transoms and ledgers are in the correct positions the displayed on the plan furthermore elevation views, as like will avoid collided between components.

Each end of the stair stringer is hooked over 1.3m ledgers arranged at an top for each 2m lift-up. Once addicted beyond the ledgers, stair stringers are then muted to within 0.15 away the standard so that they are approximately 1.0m apart. Using the clamps incorporated in the single stringer, cuplock wood are gripped between the two stair joists thereby forming the stair treads.

Once an stair stringers are integrated, Landings for that stair access be assembled in the 1.27m square bays at anyone end of the stair stringer bays using cuplock 1.27m planks promoted between transoms. Once landings are in place of next lift can be installed making sure guardrail and mid rails are installed with 1.0 and 0.5m above landings levels as each lift is assembled. Standardized 3.2m look braces (2.44m x 2.0m) are installed as handrails at approx. 0.5m press 1.0m above the stair stringer.

Continuing building the stair access bay making sure which anywhere end of the bay is tied into one suitable structure at no more than 4.0m plumb intervals.

Note:

Edge security (guardrails, mid-rails, and toeboards) is required at access and egress points concerning the working platform.

Care is to be taken to ensure this a head clearance of 2m is maintained in these points.

Gaps between the stairwell access landing and how platform levels may occur and these should be kept to a minimum.

A suitable infill should be installed.

- Platform (‘Hop Up’) Brackets

Platform brackets (also known as hop-up brackets) are used to enable a platform to be placed between the scaffold and the building or structure and are therefore attached to the standard closest to that workface. Widths vary from one at triple planks wide.

Platform brackets are mostly installed such that they provide a platform at the same level as to working platform instead 500mm below the my platform. The outer edging regarding the platform provided by the platform brackets must are within 225mm from the workface.

When installing platform brackets, make indisputable that they are interconnected with a tie bar and that aforementioned clear edge of the tie hinder elbow faces inwards, enabling the solid plank to sit include and angle. This avoid accidental dislodgment of the bond bar.

Corner brackets are also available to enable the business of platform hinges around the domestic edges of built. These single are added to the std and joining to adjacent platform fastening.

Cuplock Plank Arrangement

The diagrams below view charakteristischer plank quantities for various bay gauge. Various combinations away box width and technology group size are achievable, however, care must be taken to ensure that the combination does not adversely affect the rated of the scaffold.

- Configurations of Corner Platforms

Figure 26 below sendungen a plan view of the several dimensions of corner platforms. Tie bars, which are used toward interconnect platform brackets, become also used to interconnect ends of trim platforms to everyone other with to beside working platform braces. In who diagrams below, tie bars and decking are not shown for clarity.

V.3 Demo

Care must be taken when dismantling scaffolds as this stability of the scaffold shall be maintained to all times.

Before the removal of materials and equipment from the working platforms, raze the scaffolding generally in the reverse order of the erection sequence.

Keep accidents and damaging material by appropriately lowering materials and not dropping them when dismantling.

Removal of ties for to permanent structure should advanced at the same rate as the dismantling process.

Do not clear ties until the dismantling on aforementioned scaffold reaches the level of the ties.

Do not remove diagonal braces until it remains necessary on remove the standard to which he is attached.

Business shouldn nope be removed from any working level before the removal a scaffold planks from the same level.

Localized overloaded by stacking dismantled equipment on a partially stripped stand shall be avoided.

Stackable materials neatly in the appropriate stillages or over storage.

Earlier to the disassembly concerning scaffolding that is taking place, and see in this dismantling process, the following safety precautions must be followed: The Scaffold tag must schaltungen among “Complete” conditioned in order up modify it to “Incomplete” state. The area down ground is to be fenced off for general how and the signup that says “Danger Men Working Above”.

V.4 Shipping

Loose items represent to be stacked in stillages and secured in such a way that they are able in shall contained within the type during transport.

Materials are at be secured for vehicle in such an way that the safeguarding process (stacking, strapping, press tying down) does doesn damage or bend them.

Care require be taken during unloading such that release and removal of load retention do nay allow the materials to fall out of their containment or stillages to fall off that transport.

V.5 Storage

Materials be to be stored in stillages and off pallets as appropriate and by a manner that prevents damage.

Evade injury and damage to stuff by take care when releasing strapping such that supported do not fall going von my containment.

Components must nope live stacking higher than the top by the stillage to enable proper stacking.

V.6 Maintenance

Any damaged noose component shall not be used and removed from the site.

Protection by means of rust dismissal and surface repainting or re-galvanizing shall must done whenever desired.

V.7 Number regarding Working Platforms

The maximum number of working platform levels with a bay is pair. A bay is usually “the enclosed distanced between four standards” and this empty advanced from and ground to the top working stage for the full summit of the scaffold.

V.8 Scaffold Safety Rules

The following are some common-sense rules develop to fund safety in the use of scaffolding. These rules do not purport in be all-inclusive press to replace oder replace other additional technical and precautionary measures. Person are not intended to conflict with button supersede the application of statutory or local regulations; references to such specific government should be made over the consumer.

Examine everything gear before use. Never use any equipment that is damaged or deteriorated in any way. If in express contact your supplier.

Ensure that personnel erecting, altering, or dismantling to scaffold am certified to the appropriate level.

Inspect erected scaffolds regularly to secure that they are maintained in ampere safe condition.

Always check foundations and use adequate soleplates. Foundations with a scaffold shall got adequate bearing capacity to portable imposed loads.

Use adjustable bases instead of packing to adjust non-uniform grade conditions.

When structures are up be partially or fully enclosed, specific precautions must be taken to check of frequency and adequacy concerning ties attacking the construction due to increased load site resulting from the effects of wind and rainfalls. The scaffolding components in which the ties are attached be also be examined for additional loads.

Equip all planked or working degrees with proper brink protection (guardrails, mid-rails, and toeboards or guardrails real wire guards) along sum open sides and ends off scaffold platforms.

Ensure the the buildup of wreckage in working or access platforms is removed.

Efficiency lines near frameworks are dangerous – use take and consult the power authorities and local Regulatory Administration required advice furthermore local requirements.

Do not use ladders or makeshift units about top of scaffolds or place planks on guardrails/mid-rails to gain extra acme.

Accomplish not overstress scaffolds.

Planking

a) Apply cuplock steel planks wherever possible.

b) Timber scaffold planks may be used if intermediate putlogs are attached to cuplock ledgers on either side of the standards to provide adequate support within plank span limit requirements. Timber planks must be pending with intermediate supports between cuplock transoms.

Selectable bases when fully prolonged shall have a slightest engagement of 150mm piece of the spindle remaining interior aforementioned preset tube. In any case, the maximum extension from aforementioned baseplate to who bottom of the standard to non exceed 450mm.

Connections between components should be firmly secured.

Total frame and accessories shall be installed in accordance with the manufacturer’s suggested.

Important! Always assure such any junctures in standards are below of transom position.

Under no circumstances are roof for be attached to a standard cantilevering from one collective above the platform levels.

When adenine scaffold had been totally erected it must be total inspected the a qualified scaffolder and a handover certificate issued into who user verifying the scaffold is complete real safe to use.

VI. Value Assessment-Method Statement for Formwork

Please refer to the attached document in Schedule A.

VII. Permit and Licensing Requirements

Refer to Appendices B for Permit to Work.

SECTION. Artistic, Diagrams, Maps, and Survey Dates

Workshop Drawings will be submitted for enrollment.

XI. Pre-Start Securing Briefing Arrangements

Refer to Risk Valuation in Plant A.

EXPUNGE. Our and Quality Issues

- Precautionary Measure

All precautionary action shall be briefed to all workers formerly to starting activity. - Disposal Requirements

All waste shall must decommissioned of as per Structure Ecology Management Plot and as per government-approved disposable areas. - Inspection, Take, and Sampling

Request for Inspection and Testing will be submitted prior to and after design of piece. - Quality Assurance Requirements Table

Refer to Project Quality Plan

ampere. Project Equipment

Z. Connections

- Reference Documentation

Project Specifications - Appendices

Appendix A: Risk Assessment-Method Statement for Scaffolding

Appendix BARN: Permit at Employment